How to Pass the Six Sigma Green Belt Certification Exam Successfully

The Six Sigma Green Belt Certification validates your ability to apply structured process improvement techniques that drive measurable business results. This credential is sought after by employers in manufacturing, healthcare, finance, IT, and service sectors because it proves you can identify inefficiencies, reduce waste, and improve quality using data-driven decision-making.

Whether your goal is career advancement, salary growth, or preparing for higher Six Sigma belts, this guide outlines the exam content, study strategies, and pitfalls to avoid so you can pass on your first attempt. By combining technical expertise with disciplined preparation, you position yourself as a change agent capable of delivering lasting impact in any organization.

What the Six Sigma Green Belt Certification Covers

Core Principles and Methodologies

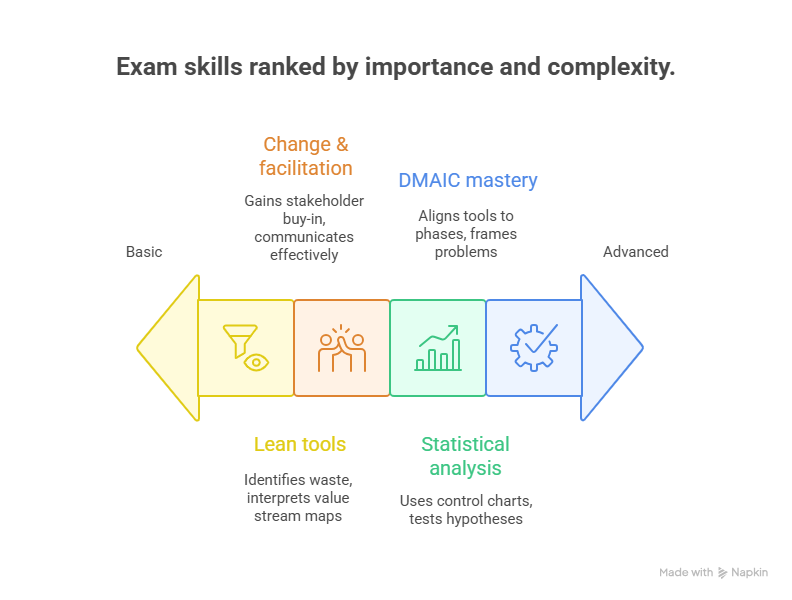

The Six Sigma Green Belt Certification centers on the DMAIC methodology — Define, Measure, Analyze, Improve, and Control — as the framework for structured problem-solving. You’ll be tested on your ability to identify process issues, collect and analyze relevant data, and implement sustainable improvements that align with business goals.

Candidates must understand Lean principles, including waste elimination, process flow optimization, and value stream mapping. The certification also emphasizes the role of Green Belts within cross-functional teams, where you support Black Belts in larger projects or lead smaller-scale initiatives independently.

Mastery involves more than memorizing steps; you must demonstrate practical application of these principles in case studies and scenario-based questions, showing you can translate methodology into measurable business results.

Process Improvement Tools

Expect significant focus on the tools required to carry out Six Sigma projects effectively. This includes cause-and-effect diagrams, Pareto charts, control charts, histograms, scatter plots, and process maps. You’ll also need to know how to perform root cause analysis using methods like the “5 Whys” and Failure Modes and Effects Analysis (FMEA).

Statistical tools such as hypothesis testing, regression analysis, and capability analysis are tested to ensure you can interpret data and validate process improvements. The exam may require you to select the most appropriate tool for a given stage in the DMAIC cycle, which demands not just familiarity but strategic tool selection skills.

Additionally, you must understand how to document improvements, create process control plans, and monitor metrics post-implementation to ensure gains are maintained over time. This toolset allows Green Belts to deliver results that are both impactful and sustainable, making their role critical to an organization’s continuous improvement culture.

Exam Structure and Key Competencies

DMAIC Framework Mastery

A large portion of the Six Sigma Green Belt Certification exam evaluates your ability to apply the DMAIC framework effectively. You must know how to:

Define project goals, scope, and deliverables clearly.

Measure process performance using accurate and relevant metrics.

Analyze collected data to identify root causes of inefficiencies.

Improve processes with targeted, data-driven solutions.

Control improvements to sustain gains long-term.

The exam tests not only the sequence of DMAIC but also the correct application of tools and statistical techniques at each stage. You’ll be presented with case scenarios where you must decide which step to focus on next and justify your decision based on the data given. This requires both methodological discipline and contextual flexibility.

Statistical Analysis Skills

Statistical competence is central to passing the exam. Expect questions requiring interpretation of control charts, hypothesis test results, regression outputs, and process capability indices. You should be comfortable with:

Descriptive statistics (mean, median, mode, standard deviation)

Inferential statistics for decision-making under uncertainty

Capability analysis (Cp, Cpk) for assessing process performance

Sampling strategies and error analysis

The exam often frames these in real-business contexts — for example, deciding if a manufacturing line meets customer specifications based on Cpk values. You’re expected to link statistical findings to actionable recommendations. This means knowing not only how to run an analysis but how to explain its business impact.

Scenario-Based Question Approach

The Green Belt exam frequently uses scenario-based questions to test applied knowledge. You might be given a narrative about a process failure, accompanied by partial data, and asked which Six Sigma tool to apply, what step of DMAIC is next, or how to interpret a given statistical result.

The key to handling these is to:

Identify which DMAIC stage the problem belongs to

Recognize the most efficient tool for that stage

Apply statistical reasoning to justify your choice

This style rewards critical thinking under time constraints and penalizes rote memorization. Practicing with real-world examples and mock exams that mimic this format is essential to scoring well.

Building an Effective Study Plan

Resource Selection and Prioritization

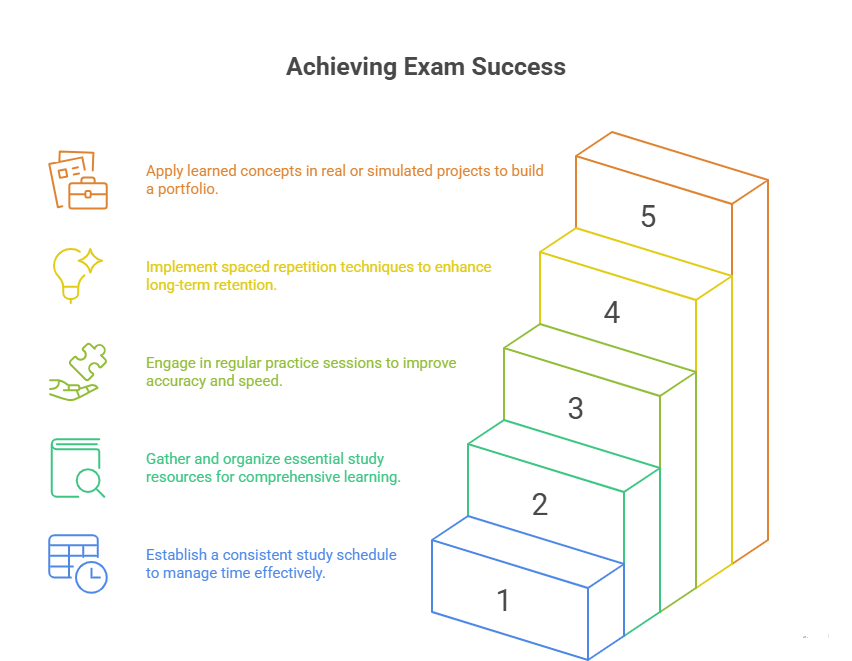

Begin with the official Six Sigma Green Belt Certification body of knowledge or exam outline from your certifying organization (ASQ, IASSC, or other). This document dictates what’s tested and should be your primary roadmap.

Prioritize high-quality resources:

Comprehensive study guides (e.g., ASQ’s “CSSGB Handbook”)

Online courses with interactive exercises and case studies

Statistical analysis references like “The Lean Six Sigma Pocket Toolbook”

Access to statistical software or simulators for practice

Rank topics based on weight in the exam and your current proficiency. Allocate more time to high-weighted areas such as DMAIC tools, statistical methods, and process improvement strategies, while maintaining regular review of supporting topics like team facilitation and change management.

Daily Practice and Review Cycles

A consistent, disciplined approach produces the best results. Aim for 90–120 minutes daily study over 6–8 weeks. Structure sessions to include:

Review of one major topic (30–45 minutes)

Practice questions or data analysis exercises (30–40 minutes)

Brief recap and flashcard review (10–15 minutes)

Integrate spaced repetition to reinforce memory — revisiting each topic multiple times at increasing intervals. Use active recall by explaining concepts aloud or teaching them to someone else.

Include weekly full-length practice tests under timed conditions. Post-test, conduct a gap analysis to identify weak areas and update your study plan accordingly. Treat incorrect answers as diagnostic tools, not failures.

Group Study vs. Solo Preparation

Group study can be powerful if structured properly. Discussing DMAIC applications, debating statistical interpretations, and working through case studies with peers can deepen understanding. However, it’s only effective when participants are equally committed and sessions stay focused.

Solo preparation offers flexibility and control over pacing, which is ideal for mastering technical topics like hypothesis testing or control chart interpretation. Many successful candidates combine both approaches — using solo time for core content mastery and group sessions for application-based learning.

If joining a study group, set clear agendas and circulate practice questions in advance. Limit sessions to 90 minutes to maintain productivity.

Mistakes That Lower Passing Rates

Memorizing Instead of Understanding

One of the most common errors is approaching the Six Sigma Green Belt Certification as a memorization exercise. Candidates often focus on recalling DMAIC steps or definitions without truly understanding how to apply them in real-world contexts. This becomes a problem in scenario-based questions where you must determine the right tool, interpret data, or choose the most effective improvement method.

To avoid this, connect each concept to a real process example. When learning about control charts, don’t just memorize formulas — analyze a sample chart and decide whether a process is stable or needs intervention. This application-first mindset ensures you can adapt your knowledge to any question format.

Ignoring Mock Test Analytics

Another mistake is taking practice exams without analyzing the results in depth. Simply noting your score isn’t enough — you must break down your performance by topic area to pinpoint weaknesses. Many candidates repeatedly miss questions in the same domain, like statistical analysis or process mapping, yet fail to restructure their study plan accordingly.

Use a structured review process:

Categorize each missed question by exam domain.

Identify patterns — is the issue lack of knowledge, misinterpretation, or calculation errors?

Allocate extra study time to those categories, using targeted resources and fresh practice questions.

By treating mock exams as diagnostic tools rather than pass/fail benchmarks, you improve precision and reduce the risk of repeated mistakes on the actual exam.

| Mistake | Impact on Score | Fix Action |

| Memorizing without application | Misses scenario questions requiring tool selection | Practice case-based drills; justify tool-to-phase choice |

| Weak statistics | Errors on control charts, capability, hypothesis tests | Daily quant reps; formula sheet; explain results in business terms |

| No mock exam analytics | Repeat mistakes; flat score curve | Tag misses by domain; remediate; re-test within 72 hours |

| Ignoring Control phase | Points lost on sustainability and monitoring | Build control plans; select proper charts and reaction rules |

| Poor time management | Unanswered questions, rushed guesses | Timed blocks; 60–90s per item; mark-and-move protocol |

Career Benefits of the Six Sigma Green Belt

Industry Applications

The Six Sigma Green Belt Certification is valued across industries because it equips professionals to lead measurable process improvements. In manufacturing, Green Belts reduce defect rates and improve production efficiency. In healthcare, they streamline patient flow, cut wait times, and enhance quality of care. In finance, they optimize transaction processes, reduce errors, and improve compliance controls.

IT and service industries also benefit — Green Belts can refine workflows, improve system performance, and increase customer satisfaction metrics. Because the certification is methodology-focused rather than industry-specific, it transfers seamlessly between sectors. This adaptability makes Green Belts a strong asset in organizations prioritizing cost reduction, quality improvement, and operational excellence initiatives.

Salary Growth and Promotions

Certified Green Belts often see a 10–20% salary increase within the first year of applying their skills in the workplace. Entry-level roles like Process Analyst or Quality Coordinator can quickly progress to positions such as Continuous Improvement Manager or Operational Excellence Lead.

Employers recognize the certification as proof of your ability to manage projects, analyze data, and deliver sustained results. These competencies make you a candidate for leadership roles, even without decades of experience.

Pairing the Green Belt with complementary credentials — like Lean certification or a project management qualification — can accelerate promotion timelines. In competitive job markets, this multi-credential approach positions you ahead of peers and increases your leverage in salary negotiations.

| Mistake | Impact on Score | Fix Action |

| Memorizing without application | Misses scenario questions requiring tool selection | Practice case-based drills; justify tool-to-phase choice |

| Weak statistics | Errors on control charts, capability, hypothesis tests | Daily quant reps; formula sheet; explain results in business terms |

| No mock exam analytics | Repeat mistakes; flat score curve | Tag misses by domain; remediate; re-test within 72 hours |

| Ignoring Control phase | Points lost on sustainability and monitoring | Build control plans; select proper charts and reaction rules |

| Poor time management | Unanswered questions, rushed guesses | Timed blocks; 60–90s per item; mark-and-move protocol |

How the Project Management Certification by APMIC Complements Six Sigma

The Six Sigma Green Belt Certification equips you with the tools to improve processes, reduce defects, and drive measurable operational gains. However, to maximize career impact, combining it with the Project Management Certification by APMIC provides a powerful blend of technical precision and strategic leadership.

Strategic and Tactical Alignment

Six Sigma focuses on improving processes within a defined scope, while the APMIC Project Management Certification trains you to manage entire projects from initiation to closure. This means you’re not only capable of optimizing workflows but also ensuring those improvements are delivered on time, within budget, and aligned with broader organizational goals.

For example, as a Green Belt you might lead a defect reduction initiative within a production line. With APMIC’s project management skills, you can plan the project timeline, secure stakeholder buy-in, manage resources, and oversee cross-departmental collaboration — ensuring the improvement project is executed flawlessly.

Broader Leadership Opportunities

Many organizations require leaders who can combine analytical problem-solving with the ability to coordinate diverse teams. Six Sigma sharpens your analytical edge; the APMIC certification demonstrates you can lead initiatives that extend beyond continuous improvement into innovation, transformation, and strategic change.

This combination also qualifies you for higher-value roles like Operational Excellence Manager, Program Manager, or PMO Lead, which involve supervising multiple projects simultaneously while maintaining alignment with business strategy.

Career Mobility Across Industries

Individually, both certifications are industry-agnostic. Together, they provide an adaptable toolkit you can apply in manufacturing, healthcare, IT, finance, logistics, and beyond. In sectors undergoing digital transformation, the ability to optimize processes while managing large-scale change projects is especially valuable.

Employers favor professionals who can integrate quality improvement methods into formal project management structures, ensuring that operational gains are not isolated events but embedded into the organization’s long-term performance.

Enhanced Earning Potential

Professionals holding both certifications often command salaries 15–25% higher than peers with only one. This is due to their dual capability: solving operational problems and delivering strategic initiatives. Hiring managers recognize that this combination reduces the need to hire separate specialists, making you a high-return investment.

By coupling your Six Sigma Green Belt Certification with the Project Management Certification by APMIC, you position yourself as a hybrid professional — equally skilled at analyzing root causes, implementing sustainable solutions, and ensuring project success from conception to delivery.

Frequently Asked Questions

-

The Six Sigma Green Belt Certification validates your ability to improve processes, reduce waste, and solve quality-related problems using the DMAIC methodology. It’s ideal for professionals involved in process improvement, operations, quality control, or project support roles. Common candidates include engineers, business analysts, operations managers, and mid-level project managers. Green Belts typically lead smaller projects or support Black Belt-led initiatives. Because the certification is methodology-focused and industry-neutral, it benefits professionals in manufacturing, healthcare, IT, finance, and service industries. For those aiming to advance into leadership or specialized operational excellence roles, this certification provides a strong foundation for measurable, data-driven improvements.

-

The exact format varies by certifying body (ASQ, IASSC, etc.), but most Green Belt exams feature 100–150 multiple-choice questions to be completed in 3–4 hours. Content is heavily weighted toward the DMAIC phases: Define, Measure, Analyze, Improve, and Control. Questions often include scenario-based problems requiring statistical interpretation, process mapping, and tool selection. Some versions are open-book, while others require closed-book conditions. A passing score typically ranges from 70% to 80%, depending on the provider. The test measures both conceptual knowledge and practical application, so preparation must include problem-solving practice, not just memorizing definitions or formulas.

-

The exam content spans five core DMAIC phases:

Define: Project charters, stakeholder analysis, and problem statements.

Measure: Process mapping, data collection planning, and baseline measurement.

Analyze: Root cause analysis, hypothesis testing, and regression.

Improve: Solution generation, pilot testing, and risk mitigation.

Control: Control charts, standardization, and process monitoring plans.

Statistical concepts like capability analysis, sampling, and error types are also tested. In addition, candidates must understand Lean principles, waste elimination, and facilitation skills for leading project teams. The combination of technical and soft skills ensures that Green Belts can manage projects effectively from start to finish.

-

Most candidates require 6–10 weeks of focused preparation, assuming 1–2 hours of study per day. Your exact timeline will depend on your familiarity with statistics, Lean concepts, and project management. Begin with the official body of knowledge from your certifying organization to prioritize study topics. Allocate more time to high-weighted areas like Analyze and Improve, while maintaining consistent review of foundational concepts in Define and Measure. Incorporate weekly mock exams to monitor progress and adjust your study plan. For maximum retention, use a mix of reading, problem-solving, and application through case studies or workplace projects.

-

Effective preparation combines official course materials, high-quality reference books, and practical application tools. Recommended resources include the “ASQ Certified Six Sigma Green Belt Handbook,” “The Lean Six Sigma Pocket Toolbook,” and online training platforms like GoLeanSixSigma or Coursera. Use statistical software like Minitab or SigmaXL to practice data analysis. Flashcards help reinforce definitions and formulas, while practice exams simulate the test environment. The best approach blends theory with real-world application — applying DMAIC steps to actual projects or case studies deepens understanding and improves recall during the exam. Avoid relying on a single source; diverse resources build a stronger knowledge base.

-

The top mistakes include:

Memorizing terms without application skills — scenario-based questions require practical problem-solving.

Neglecting statistical analysis — failing to interpret control charts or capability indices can cost major points.

Skipping mock exam review — taking practice tests without analyzing results misses valuable learning opportunities.

Ignoring time management — spending too long on complex questions reduces overall completion.

Underestimating the Control phase — many candidates focus on improvement but neglect sustainability methods.

Avoid these pitfalls by balancing content review, timed practice, and error analysis throughout your preparation.

Final Thoughts

Passing the Six Sigma Green Belt Certification exam requires more than understanding DMAIC theory — it demands the ability to apply process improvement tools in real-world contexts. By focusing on statistical analysis, strategic tool selection, and scenario-based problem solving, you position yourself to excel on the first attempt.

Approach your preparation with discipline, using official bodies of knowledge, targeted resources, and consistent practice testing. The Green Belt isn’t just an exam — it’s a long-term investment in your ability to drive operational excellence and create sustainable value in any organization.

| Which Six Sigma Green Belt topic do you find most challenging? | |